No empty promises

How can we as a plastic manufacturing company reduce our ecological footprint? That is the question we implement into our daily approach.

At Gevaplast we are hands-on through all levels, our promise for a sustainable approach we engage with our clients, included. Since 2015 we have developed an environmental management system, IS0 14001:2015, and every day we work to maintain and optimize this system.

From purchasing fruit at work through a local bio farmer and searching for sustainable raw materials for our products, to following the environmental legislation that we need to apply to as a manufacturer.

Raw material

For our insulators we use raw material that comes from our own grinding mill, in that way we make up for the loss of our own products.

Robot

For the production of toy components for TomTect we have a robot that already removes excess plastic out of the mould during the production process and grinds it, to immediately reuse again.

Recycling

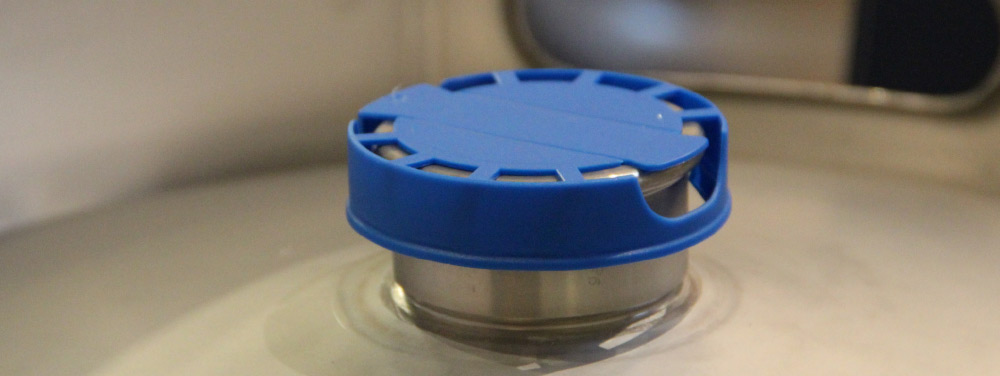

At the moment we are fully running tests to use recycled material for the production of our dish caps. A huge challenge where we bombard our raw material suppliers with lots of questions and follow closely the developments. The biggest challenge remains to produce the recycled materials in such way that we can keep guaranteeing our quality. The first tests are already promising!

With our American partner PakTech we found a great alternative for the packaging of cans. They use Post Consumer Recycled material for the production of can holders. This material is 100 % made out of milk crates, amongst others, and is also recyclable again.

They explain it very well in this video.

Environmental management system

At Gevaplast we worked hard to achieve the IS014001 certificate. The combination of this environmental management system and our quality management system, ISO 9001:2015, ensures that we keep in mind environment as well as quality during every process at our company, from buying and production to logistics.

Working together

on sustainability?

Ask a question to our R&D department! We aim together to make your company more durable as well by optimizing your packaging, products and supply chain management.